Every pill you swallow has a story. Not the kind you read in a novel, but a digital trail of numbers and codes that tell you where it came from, when it was made, and who handled it along the way. This isn’t science fiction - it’s the only thing standing between you and a fake medicine that could kill you.

Why Lot Numbers and Serial Codes Matter More Than Ever

In 2023, the FDA reported over 1,200 cases of counterfeit drugs in the U.S. alone. Some were filled with chalk. Others contained rat poison. A few even had the wrong active ingredient - the kind meant for pets, not people. These aren’t rare accidents. They’re the result of broken supply chains and weak tracking systems. Lot numbers and serial codes are the answer. A lot number identifies a group of products made together under the same conditions - same batch, same machine, same day. A serial code is unique to each individual unit. Think of it like this: a lot number tells you which cake came out of the oven. The serial code tells you exactly which slice you got. In pharmaceuticals, this distinction saves lives. When a bad batch of blood pressure pills is found to have too much active ingredient, regulators don’t need to pull every pill ever made. They just pull the ones with that one lot number. That’s precision. That’s safety.How Track-and-Trace Works in Real Life

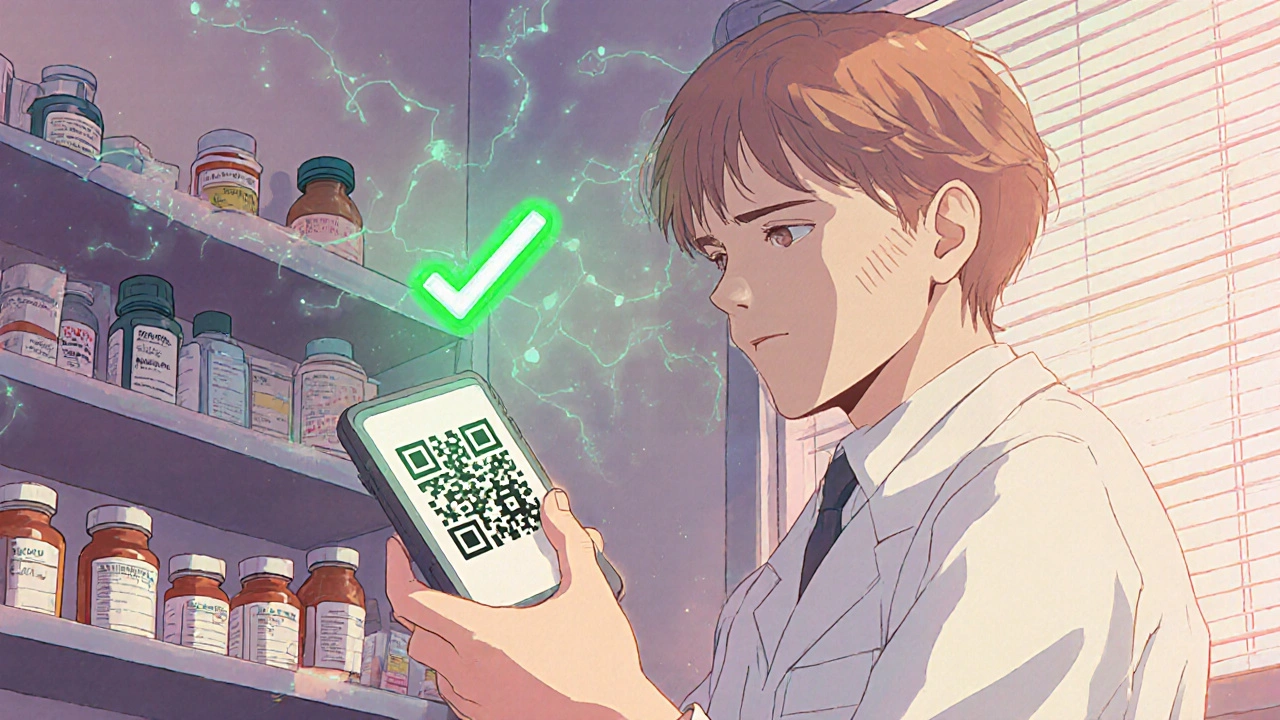

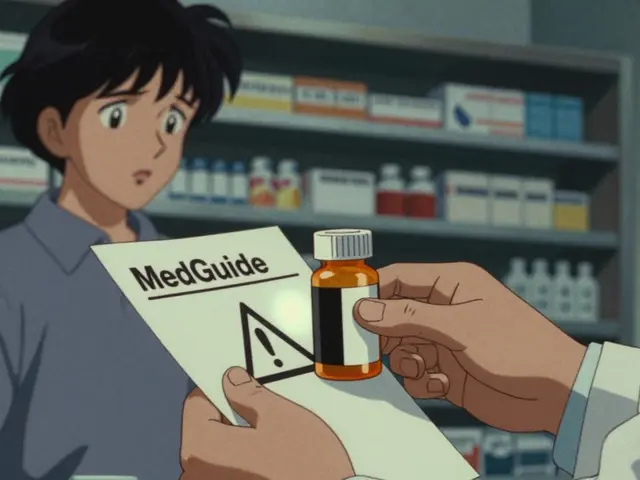

It starts at the factory. When a batch of 10,000 tablets is produced, the machine prints a lot number directly onto the packaging. That number includes the date, shift, production line, and raw material source. Each bottle gets a unique serial code - often printed as a QR code you can scan with your phone. From there, every handoff is recorded. The distributor scans the lot and serial codes when they receive the shipment. The pharmacy scans them again when they stock the shelves. Even the patient’s pharmacy system might log the code when the prescription is filled. If something goes wrong - say, a tablet is found to be contaminated - the manufacturer can trace the entire path. They know exactly which stores got which bottles. They can alert customers by lot number. They don’t have to shut down the whole product line. That cuts recall costs by up to 63%, according to FDA case studies.The Difference Between Lot and Serial Tracking

Not all drugs need the same level of tracking. For a bottle of generic ibuprofen, a lot number is enough. Each pill in that bottle is identical. If one is bad, they’re all potentially bad. But for high-value or high-risk products - like insulin pens, cancer drugs, or implantable devices - serial codes are mandatory. Why? Because each unit has a unique history. One insulin pen might have been stored at the wrong temperature during shipping. Another might have been tampered with. Only a serial code can pinpoint which one. In medical devices, serial tracking reduces shipping errors by 89%. In pharmacies, it cuts down on expired or recalled products sitting on shelves. A 2023 study in a major Canadian hospital found that after implementing serial code scanning, they eliminated 94% of expired drug dispenses.

Regulations That Made This Necessary

This system didn’t appear out of nowhere. It was forced into existence by tragedy. Back in 1937, over 100 people died after drinking a toxic liquid antibiotic called Elixir Sulfanilamide. There was no way to track where it came from. No way to recall just the bad batches. That disaster led to the 1938 Food, Drug, and Cosmetic Act - the first real law requiring batch identification. Fast forward to 2011. The FDA passed the Drug Supply Chain Security Act (DSCSA), which set a 10-year timeline for full track-and-trace implementation. By 2023, every prescription drug in the U.S. had to carry a unique serial number. By 2025, every wholesaler, distributor, and pharmacy must be able to verify those codes electronically. The EU is even stricter. Starting in 2027, the Digital Product Passport will require serialized tracking for medicines, batteries, electronics, and textiles. Canada’s Health Canada has followed suit with similar rules under the Safe Drugs Act. This isn’t optional. It’s the law. And the penalties for non-compliance? Fines up to $1 million per incident. FDA warning letters. Criminal charges.What Happens When Tracking Fails

In 2022, a small Canadian pharmacy received a shipment of metformin with mismatched lot numbers. The packaging looked right. The label was perfect. But the barcode didn’t match the manufacturer’s database. They didn’t know it was fake. They sold 400 bottles before the system flagged it. By then, two patients had been hospitalized with dangerously low blood sugar. The pharmacy lost its license. The manufacturer sued. The fake drug was traced back to a lab in China. This happens more than you think. A 2024 investigation by the Canadian Pharmacists Association found that 1 in 15 counterfeit drug cases went undetected because the lot or serial code was copied perfectly - but never registered in the official database. The fix? Systems that don’t just scan codes - they verify them in real time against a national registry. That’s what the DSCSA’s National Drug Code (NDC) system does. Every code must be registered before it’s shipped. If it’s not in the system, it’s rejected.

How Small Pharmacies and Clinics Can Comply

You don’t need a billion-dollar IT department to make this work. Most modern pharmacy management systems - like QS/1, Rx30, or even cloud-based platforms like DrFirst - come with built-in lot and serial tracking. All you need is a $50 barcode scanner and a few minutes of training. Here’s how to get started:- Scan every incoming shipment - don’t just accept it on faith.

- Match each lot number to the manufacturer’s official list. If it’s not there, hold the shipment.

- For high-risk drugs, record the serial code when you dispense it. That way, if a patient has a reaction, you know exactly which pill they took.

- Train your staff to treat codes like passwords - if it doesn’t scan, it’s not real.

The Future: AI, Blockchain, and Real-Time Alerts

The next wave is smarter. Systems now use AI to spot patterns. If a lot number shows up in three different countries in one day, the system flags it. If a serial code is scanned twice in the same week - once at a warehouse, once at a street vendor - it’s likely fake. Blockchain is being tested to create tamper-proof logs. Once a code is registered, it can’t be changed. Every movement is recorded. No backdoors. No lies. And soon, IoT sensors will track temperature and humidity during transport. If your insulin was exposed to 90°F for 12 hours, you’ll get an alert before you even open the bottle. By 2027, your phone might automatically verify a drug’s authenticity the moment you scan the code at the pharmacy counter. No apps. No login. Just a green checkmark.What You Can Do Right Now

You don’t have to wait for the future to stay safe.- If you’re a patient: Always check the packaging. Does the lot number match what’s on the manufacturer’s website? Can you scan the QR code and get a real result?

- If you’re a pharmacist: Never skip the scan. Don’t trust the label. Trust the code.

- If you’re a supplier: Make sure your system can verify codes against Health Canada’s or FDA’s registry. If it can’t, upgrade.

What’s the difference between a lot number and a serial code?

A lot number identifies a group of products made together - like all the pills from one batch on a specific day. A serial code is unique to each individual item - like a fingerprint for one bottle or one pill. Lot numbers help recall entire batches. Serial codes track each unit’s journey.

Why do counterfeit drugs still get through if there’s track-and-trace?

Fake drugs often use copied or stolen codes that look real. The system only works if every code is verified against a live database. If a pharmacy just checks the label and doesn’t scan and confirm the code in real time, the fake slips through. That’s why scanning and electronic verification are mandatory - not optional.

Can I check a drug’s authenticity myself?

Yes. Many manufacturers provide free verification tools on their websites. Scan the QR code on the packaging with your phone. If it takes you to the official site and shows a match, it’s real. If it goes to a random site, gives an error, or says the code isn’t registered - don’t take it. Report it.

Do all countries require track-and-trace for drugs?

Most major economies do. The U.S., Canada, EU, UK, Japan, and Australia all have strict serial code requirements. Some countries are still catching up, which is why counterfeit drugs often enter through regions with weak enforcement. Always assume a drug bought overseas or online may not be verified.

What happens if a pharmacy doesn’t use track-and-trace?

They risk FDA or Health Canada penalties - fines, license suspension, or criminal charges. More importantly, they put patients at risk. In 2023, a U.S. pharmacy lost its license after distributing untracked insulin that caused two diabetic emergencies. The code was fake, but they never scanned it.

Is track-and-trace expensive to implement?

Not anymore. Basic systems start under $1,000 for small pharmacies - a barcode scanner, a free app, and a few hours of training. Cloud-based platforms like DrFirst or QS/1 include it in their monthly fee. The cost of not doing it - lawsuits, recalls, lost trust - is far higher.

13 Comments

So let me get this right... if I scan a pill bottle and it says 'valid', but the pharmacy never checked the database... I'm still at risk? That's like having a lock on your door... but leaving the key under the mat. 😑

OMG I JUST REALIZED I NEVER SCAN MY MEDS 😭 I mean, I look at the label, but I never even thought to check the QR code... I just assumed it was legit. This is terrifying. I'm scanning everything from now on. Thanks for the wake-up call.

Lot numbers are like the fingerprints of a batch serial codes are the soul of each pill. We think we live in the age of information but we still treat medicine like it's a lottery. Imagine if every car had a VIN but you only checked the color before driving. We need more than tech we need awareness.

Stop skipping scans. That’s not laziness-that’s negligence. I work in a clinic and we’ve caught three fake shipments in six months just by scanning. If your system doesn’t verify against the FDA database, you’re not compliant-you’re a liability. Get the scanner. Train your staff. Do it now.

I used to think fake pills were a movie thing. Then my grandma got sick after taking her blood pressure meds. Turned out the bottle looked perfect-same logo, same color-but the QR code led to some sketchy site in Romania. She’s okay now but I still get chills. I scan everything now. Even aspirin.

This is such an important topic. I’ve been scanning my prescriptions since the DSCSA rollout and honestly? It’s made me feel way safer. Even if it’s just a few seconds-it’s peace of mind. And for small pharmacies? The tools are cheap now. No excuse not to do it. Seriously, just get a $50 scanner. Your patients will thank you.

Actually, the FDA’s NDC system doesn’t require real-time verification until 2025. You’re conflating the mandate with current capability. Also, blockchain isn’t being ‘tested’-it’s already live in pilot programs with Pfizer and Merck. And IoT sensors? Those are for controlled substances only. Don’t overhype. 🤓

Y’all are right to be scared-but also don’t panic. The system works when we all do our part. Pharmacies scan. Patients check. Regulators enforce. It’s not perfect but it’s way better than 2010. I’ve seen the difference firsthand. Keep scanning. Keep reporting. We’re getting there.

Why should we trust American pharma anyway? They charge $500 for insulin that costs $5 to make. Now they want us to believe their codes are sacred? Maybe the real problem is profit-driven greed-not fake pills. Let’s fix the system that makes counterfeits profitable. Not just scan the bottle. Burn the whole pyramid.

I just read this entire post. Twice. And I’m still shaking. I never realized how many people could be affected by one unverified lot number. It’s not just about safety-it’s about dignity. People deserve to know that the medicine they take won’t kill them. Thank you for writing this. I’m sharing it with everyone I know.

It is imperative to underscore that the implementation of track-and-trace protocols constitutes a non-negotiable pillar of pharmaceutical integrity. The confluence of regulatory mandates, technological feasibility, and ethical obligation renders non-compliance not merely a procedural lapse, but a catastrophic dereliction of duty. One must, therefore, advocate for immediate, universal, and meticulously documented adherence to serialized verification protocols across all tiers of the supply chain.

So... we're spending millions to scan pills... but people still buy fake ones off Instagram? Maybe the real issue is that we let people buy meds online without a prescription. Fix that first. 😴

Let’s be honest: this is all performative compliance. Blockchain? IoT? Please. The real innovation is the profit margin on the $100 insulin pen that’s been sitting in a warehouse for 18 months. The ‘track-and-trace’ system is just a PR stunt wrapped in compliance jargon. We’re optimizing for liability, not lives. 🤷♀️💎